Superfine Calcium Carbonate

Application: Fillers for rubber and plastic.

Form: Powder

Surface coating: Fatty acid

Package: 25kg/bag, 500 kg/bag

Packaging: Standard package, blank package

Certifications: ISO 9001

Product is in compliance with REACH & RoHS requirements.

DIACAL CC is a ultra-fine calcium carbonate which has 60 nm of primary particle size. These particles are surface coated with fatty acids in order to improve dispersion property at the mixing stage with organic materials. DIACAL CC will enhance the mechanical strength of polymer and other organic materials when used.

For DIACAL CC series, two different specifications are available as below.

| DIACAL CC-E Whiteness (%): 93 min. Specific Gravity (g/cm3): 2.56 Bulk Density (g/mL): 0.80 max. Surface Coating: Fatty Acid Oil Absorption (mL/100 g): 16 ~ 30 CaCO3 Content (%): 96 min. Moisture Content (%): 1.00 max pH value: 9.0 ~ 9.8 |

DIACAL CC-A Whiteness (%): 93 min. Specific Gravity (g/cm3): 2.56 Bulk Density (g/mL): 0.78 max. Surface Coating: Fatty Acid Oil Absorption (mL/100 g): 18 ~ 30 CaCO3 Content (%): 96 min. Moisture Content (%): 1.00 max pH value: 9.0 ~ 9.8 |

Compound Guide

Natural Rubber (NR): Show the best results.

Isoprene Rubber (IR): Show the best results.

Butadiene Rubber (BR): Show satisfactory results.

Styrene-butadiene Rubber (SBR): Show satisfactory results.

Chloroprene Rubber (CR): Show satisfactory results.

Butyl Rubber (IIR): Show excellent results.

Hypalon (CSM): Show excellent results.

Reclaimed Rubber: Show excellent results.

Polyvinyl Chloride (PVC): Show excellent results

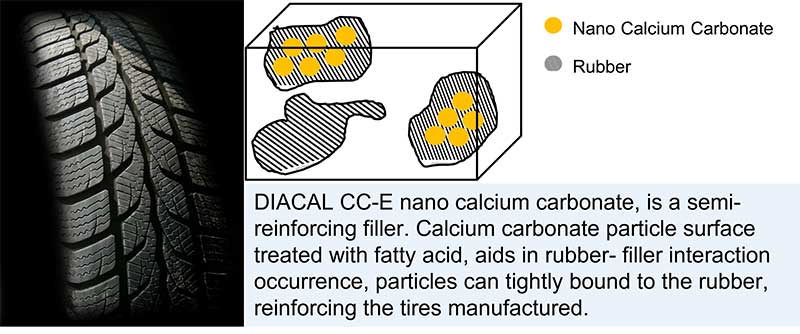

Usage of DIACAL CC in tyres

DIACAL CC surface treated with fatty acids, has the ability to mix evenly into the rubber matrix, allowing high loadings with fillers bounded tightly. Rubber matrix loaded with DIACAL CC nano calcium carbonate, exhibits better rubber-filler interactions, the particles aid in bounding the rubber therefore is able to reinforce the tyres manufactured.

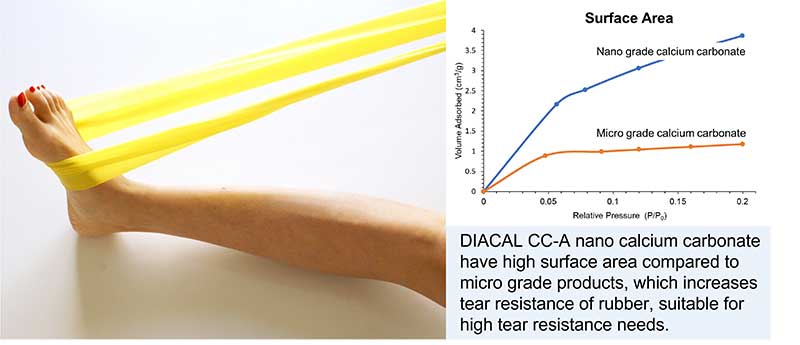

Usage of DIACAL CC in resistance bands

DIACAL CC is of nano-grade, which has much higher surface area compared to other micro grade calcium carbonate. DIACAL CC nano calcium carbonate have higher surface area, therefore is able to better contact with the rubber matrix, thus increasing tensile strength and tear resistance of rubber products.

Product Inquiry

We provide customized OEM and ODM solutions for agriculture liquid fertilizers and nanometer calcium carbonate. Contact us today to discuss your specific needs and discover how our innovative solutions can elevate your products and business.

Download

Download